Press Optimization — Getting the Fundamentals Right

In the last issue of The Flexcel Tom Kowalski, Global Printing Applications Specialist, explained what goes into optimizing the platemaking operation and described a five-step plate room audit. But to take advantage of the productivity benefits and to produce high-quality work consistently and cost-effectively, optimization has to extend into the pressroom. Which is where Tom takes us in his second article…..

More than a decade of enhancements to KODAK FLEXCEL NX Technology has addressed many of the variables that previously gave flexo a reputation for inconsistency. By building on features such as true flat-top dots and pixel-for-pixel (1:1) image reproduction, FLEXCEL NX Technology has eliminated the guesswork in prepress, enabling printers to rely on more predictable press performance.

Since 2008, some of the most important enhancements of the technology have been advanced plate surface patterning, beginning with DIGICAP NX Patterning (2010), followed by NX Advantage with Advanced Edge Definition (2016), and most recently by PureFlexo™ Printing (2021), accessed through the FLEXCEL NX Print Suite. These are founded on an in-depth understanding of how ink properties, release characteristics, plate properties, and on-press factors like impression level and anilox volume, interact to influence print quality and operational efficiency of the printing press.

But, getting the most out of advanced plate surface patterning depends on having an optimized press. Optimization becomes even more important as printers go beyond CMYK and explore technologies such as ECG printing, because of the greater degree of difficulty of each job. PureFlexo Printing is a good example: while it makes ECG simpler to implement, its performance depends on an optimized press.

Press optimization means balancing and standardizing the performance of the various components of the printing process, so that they consistently produce the precise, repeatable print that color management depends on, and brands insist on. Optimization involves many factors — more than I can cover in this article — but there are some essential characteristics of the press that, properly monitored and maintained, are the foundation of an optimized pressroom.

Run a clean, regularly-serviced press

Run a clean, regularly-serviced press

Just as in the plate room, optimization in the pressroom starts with regular servicing, at least servicing annually. It’s important, too, to keep the pressroom clean. Just as a top restaurant shows pride in its clean kitchen, so a clean production environment is a sign of a conscientious printer. Cleaning as you print creates a mindset in which process control can flourish.

Look after cylinders, rollers and sleeves

The condition of cylinders, rollers and sleeves is a critical factor in optimization — they need to be close to perfectly round — so impress on the press crew how important it is to handle them carefully during production. Roundness is expressed in terms of Total Indicated Runout (TIR), which is a measure of the radius of the cylinder/roller/sleeve from the center to the outer surface. Out-of-roundness of a couple of thousands of an inch will produce print defects and call for repair or replacement.

Monitor anilox roll wear

Monitor anilox roll wear

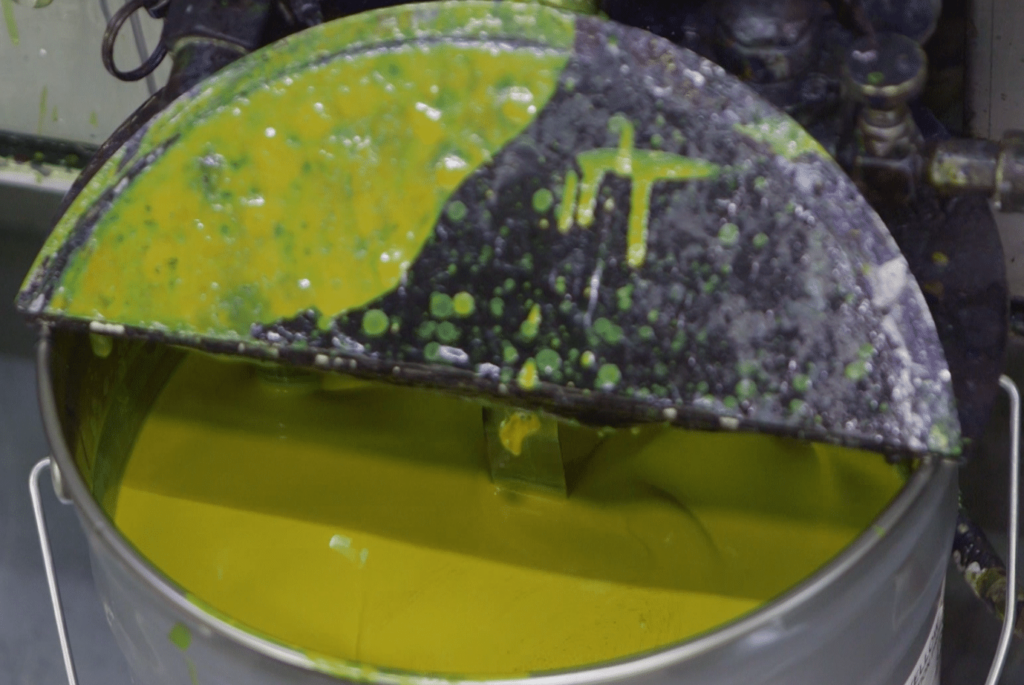

Choosing the correct anilox volume for the screen count is important, but over time the friction generated by twin steel blades running in high-speed contact with the ceramic surface of the anilox causes wear and impacts on volume. While, for a time, it is possible to adjust pigment load to compensate for wear, it gets to a point where this is no longer possible due to the ink film being too thin. Typically, a fall in volume of 15% indicates that the roller should be resurfaced. So, it is important to put in place a program to measure and inventory anilox rolls, either through your internal quality control procedures or via your anilox supplier.

Calibrate servos

Establishing and maintaining the correct nip point speed is important for extracting the most from advanced plate surface patterning, and the nip point speed depends on correct calibration of the servo motors driving the print stations. For an analogy, consider what happens when you press a fingertip on your skin and move it from side to side. If the nip point speed is wrong something similar occurs when the plate meets the substrate, causing friction and heat.

Higher pressure typically causes higher dot gain, which reproduces a smaller tonal range. Because the nip point speed — and hence the pressure on the plate — are determined by the mounting tape pressure, optimization involves establishing the speed and pressure that provide the best dot gain, density and plate wear characteristics, extending the tonal range.

Patterns call for lower viscosity inks

The excellent ink transfer that is a hallmark of FLEXCEL NX Technology depends on more than just selecting the best advanced plate surface pattern for the job in hand. Ink viscosity is another important consideration when optimizing the press to print using plates with advanced plate surface patterning, especially the micro-channel patterns used in PureFlexo Printing. As remarkable a technology as PureFlexo Printing is, capable of achieving densities at much lower pressures and with much wider latitude on press, you still need to optimize the press for it, because if the ink is too viscous it will not flow efficiently into the channels. Thinner ink films mean that adjustments will also need to be made to the dry rate. To learn more about how patterns help optimize print performance, see Your Pattern = Your Productivity.

Optimization also means ensuring that the specific FLEXCEL NX target densities for CMYK — 1.1 (yellow), 1.45 (magenta), 1.55 (cyan) and 1.65 (black) +/- 0.05 — are maintained on the press to control gain, density and color reproduction. The best way to achieve this is to have the ink blended so that at running viscosities they achieve the required density. On modern presses you can expect automated process control of ink viscosity and temperature.

Optimization also means ensuring that the specific FLEXCEL NX target densities for CMYK — 1.1 (yellow), 1.45 (magenta), 1.55 (cyan) and 1.65 (black) +/- 0.05 — are maintained on the press to control gain, density and color reproduction. The best way to achieve this is to have the ink blended so that at running viscosities they achieve the required density. On modern presses you can expect automated process control of ink viscosity and temperature.

Miraclon is here to help

If you put in place the processes I have described you will be well on the way to achieving an optimized printing workflow. And remember that comprehensive application support is available through Miraclon’s Technical Support teams, who are on hand to design and implement optimization programs based on each customer’s specific needs. Press room audits are included as part of a Miraclon Technical Support Plan to ensure you are running as efficiently as possible. Remote audits are a great option for fitting an audit into a hectic schedule: For more information on remote audits see Remote audits: support when you need it or contact your local Miraclon representative to schedule.

Tom says:

Tom says:

“Plate process optimization can prevent issues arising, improving plate quality and longevity and maximizing your potential in both the plate room and on press.”