How to use Invert Trim Waste to cut solvent costs in printing platemaking

The increase in solvent costs has sharpened the focus on cost savings and hitting sustainability targets through reducing solvent use. A simple to implement feature of the KODAK FLEXCEL NX System, the Invert Trim Waste, prevents unused plate space being washed away in platemaking, reducing the need for virgin solvent.

An easy way to cut costs in platemaking

All industries are under pressure to save energy and simplify their processes to reduce costs. It’s no different for flexographers making printing plates: across the packaging value chain, people are asking “how can I save money?”

The FLEXCEL NX System offers a wide range of ways to reduce waste and cut costs. One of those is the Invert Trim Waste (ITW) feature.

ITW is a feature in TIFF Assembler Plus (TAP) Software and FLEXCEL NX Central Software that can help bring down platemaking costs by reducing washout solution usage. In areas of the raw plate not used by customer files – identified as the waste area – the photopolymer is not exposed and gets washed away during plate processing.

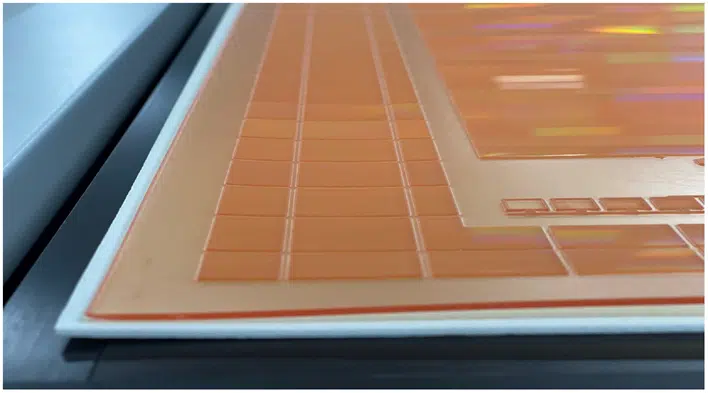

ITW enabled.

How ITW builds solvent savings into your process

When enabled, ITW starts at a distance from the imaged areas and is structured to allow solvent to flow and does not trap excess solvent. The user can specify a border value, determining how close the ITW pattern gets to the customer files. ITW then automatically fills unused portions of a plate layout file with an engineered exposure pattern. When the resulting film is used for plate exposure, the photopolymer in waste areas is crosslinked and isn’t washed away, saving solvent.

With solvent-based plate processing, plate washout solvent is used to dissolve the unexposed photopolymer, leaving the desired exposed image on the flexographic printing plate. Solvents are then reclaimed by distillation, and then returned to their optimal processing state. Through this distillation, typically 85-90% of the solvent can be recovered and reused once brought back to its original strength. As the cost of solvent increases, the importance of reclaiming less solvent plays a greater role in cost savings and sustainability.

The ITW feature is configurable by layout setup, so it’s easy to try on a limited number of jobs to see how it works within your platemaking operation. In fact, we recommended, as with all new system changes, applying ITW to one or two sheets and checking if there any issues in platemaking before implementing it across more plates, especially with automatic cutting systems. ITW is available today and once tested to confirm no issues, it can be implemented across all platemaking for efficiency and cost benefits.

Working with our customers, we see about 18% of the image volume of FLEXCEL NX Plates is made with ITW switched on, and 10% of the imaged volume with it switched on for 100% of the jobs. This indicates the tool’s high functionality, allowing platemakers to control the process and reduce costs. The feature has been proven effective on more than half a million square meters of manufactured plates since its first production.

Despite this established usage in the plate rooms, 80% of FLEXCEL NX Plates are being made without ITW activated, resulting in creased solvent and energy used, and more virgin solvents added to process these plates.

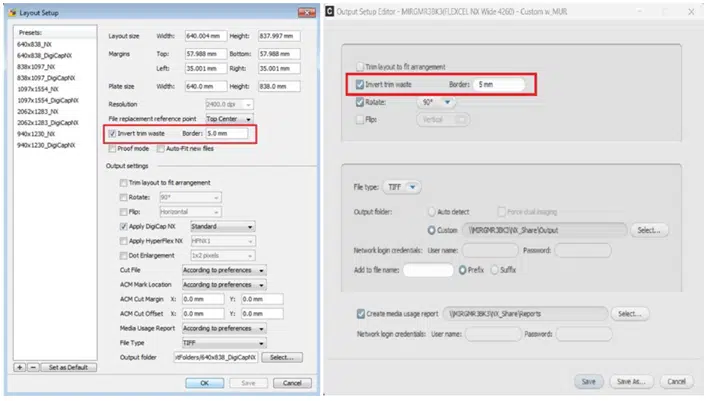

In TAP, ITW is located within the Layout Setup. In FLEXCEL NX Central Software, ITW is located within Output Setup.

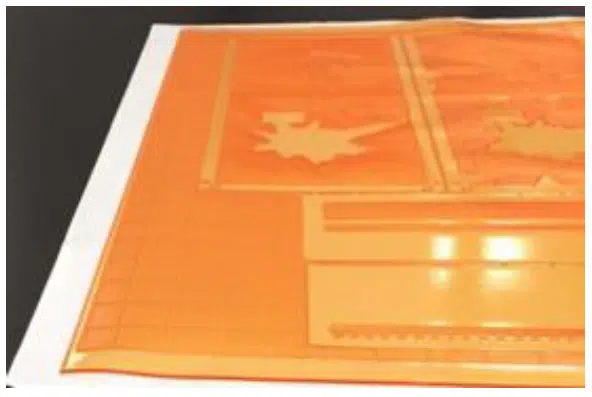

Left: Traditional Layout. Center: Output with ITW disabled. Right: Output with ITW enabled TAP v4.0.

Reduce the cost impact of unused plate space

Within wide flexible packaging, the percentage of the plate used depends on the size of the plates to be imaged versus the sheet size: the smaller the difference, the more efficiently the plate can be used, but often 25-35% of the sheet can be unused after imaging.

The same is true with narrow webs with smaller sheet plates. Often the most efficient platemakers mix wide web in the middle and narrow web around the outside to reduce the unused plate areas to 8-12%.

The unused plate area has no real economic value to the platemaker, it is just waste. But as it is a non-image area, it gets washed out to the floor, using more solvent than is needed for imaging and leading to more dissolved photopolymer. This increases the solvent distillation and reclamation costs.

One of the ways to reduce the solvents used in platemaking with levels of unused plate space is to image the unwanted areas with ITW, reducing the area to be dissolved and washed.

The savings from using less solvent

The total levels and cost of solvent and plate waste in platemaking show the potential savings that can be made with the ITW feature.

Globally, the average plate waste is 30%, meaning four gallons of solvent are used to wash out one m^2 of thin photopolymer plates. Meaning, one million m^2 of photopolymer plates can require up to four million gallons of solvent.

If we can image 2/3 of the unused image area, this can reduce the solvent usage by 10-20% in plate processing.

In the example above, the solvent usage per plate is reduced from four gallons to 3.2-3.6 gallons, which assumes a mid-point at 3.4 gallons. Meaning for the same one million m^2 of photopolymer, 3.4 million gallons of solvent are needed, rather than four million gallons. This potentially means a savings of 600,000 gallons of recycled solvent.

In addition to the significant cost savings achieved by ITW, associated costs with distillation such as recycling, related transportation costs, and labor costs contribute to the overall savings.

Commonly for a single site, the ITW feature can save roughly 20% of solvent consumption, creating savings of $1.75 per m^2 of plate material washed out, based on 2020 pricing. Ultimately, if a usage of three thousand m^2 per year is consumed, savings of over $5000 can be seen annually.

John says:

“Despite this established usage in plate rooms, 80% of FLEXCEL NX Plates are being made without ITW activated, resulting in increased solvent and energy use, and more virgin solvents added to process these plates.”