How to Mount and Demount Plates Properly

Following a few simple steps when mounting and demounting helps get the most from your plates.

Best practice plate mounting and demounting are key components to achieving quality print results. Using appropriate techniques and proper cleaning agents during the mounting and demounting process can allow for longer life on press, prolong plate life and mitigate plate remakes.

Plate handling during mounting

Extra care must be taken to protect the plate from abrasions. Small features on the plate can be especially susceptible to handling damage.

Cleaning before mounting

It is essential to start with a clean surface. This includes the cleaning of the back side of the plate, which often contains residue from the flexographic platemaking process. Additionally, a clean cylinder is needed to ensure mounting tapes are secured without any residual build up from tape residue, grease and inks.

Note: Automatic plate cleaners do not clean the base side of the plate, so cleaning the base side of the plate is necessary.

Requirements: Isopropyl alcohol or approved solvent

- To remove contaminates from the plate, gently wipe the back of the plate with isopropyl alcohol and dry with a lint free cloth.

- To remove contaminates from the plate cylinder, wipe the cylinder with isopropyl alcohol, and dry with a lint free cloth. If the cylinder has a significant build-up of debris, clean first with a more aggressive approved solvent, followed by isopropyl alcohol and drying with a lint free cloth.

- It is critical to always perform a final wipe with isopropyl alcohol to prevent plate lift or over-adhesion caused by chemical interactions with residue left on the back of the plate from other solvents.

Applying mounting tape to the print cylinder

It is important to ensure the mounting tape is uniformly adhered to the print cylinder to avoid any raised surfaces from air pockets or debris. A raised surface can lead to print artifacts.

- Apply the mounting tape to the print cylinder using uniform pressure.

- Avoid overlapping the mounting tape where it is spliced. This could have a negative impact on the print image.

Mounting the plate

Regardless of the mounting device being used, it is essential to apply uniform pressure to the plate when mounting. This will reduce the risk of having air pockets between the plate and mounting tape. A raised surface can lead to print artifacts.

Note:

- When positioning the plate on the cylinder, avoid placing sensitive image areas over the tape seam. This can cause the seam to be visible on the print image.

- If a primer pen is used to prevent edge lift, verify compatibility with the plate and the tape. Some primer pens have aggressive adhesion promoters that can make removal of the plate difficult, resulting in damage.

- Once properly mounted, use a brayer on the surface of the plate to ensure a secure bond. This will reduce the risk of plate lifting during extended press runs.

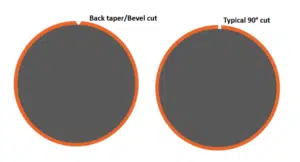

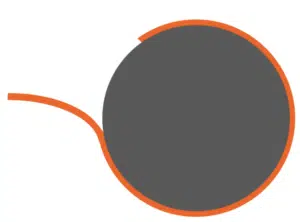

- If the plate contains large reverse print areas, it should be trimmed with a back taper/beveled edge to reduce the risk of plate lift.

- Full reverse plates trimmed at the standard 90 degree angle have the propensity to scoop ink, which subsequently travels under the plate gap and can ultimately exacerbate plate lift.

Demounting the plate

- Remove the plate in a uniform motion, pulling from a low angle (90 degrees or less).

- The slower you pull, the greater the peel force. Pulling slowly will limit the risk of plate tear and remakes, as well increasing plate life.

- Utilizing a higher angle of dismount could result in a damaged plate.

- When removing the plate from the cylinder, pull the plate in a slow, even motion.

- Be sure to keep the angle of dismount less than 90 degrees to reduce the risk of damaging the plate.

- After demounting the plate, properly clean the store the plates until the next press run. Proper storage and cleaning will prolong the life of the plates. For more information, please refer to: Cleaning plates before mounting and after printing: Partner Place Answer ID: 62385

Tom says:

Following best practice for mounting and demounting plates doesn’t just mean getting the best results on the press.

Following best practice for mounting and demounting plates doesn’t just mean getting the best results on the press.

These steps will also create plates that stand up to longer runs, have a longer life for repeat jobs and mitigate against remakes.

Discover our best practice tips.