Working differently. Meeting demand. Driving up quality. Continuing to innovate. We ask industry experts to tell us what they see today and tomorrow, as the global pandemic continues to impact the way we do business...

A whole quarter has gone by since the world started to go into lockdown to battle the pandemic and the impact of that unprecedented move is being felt far and wide. So how is it reshaping the flexo industry today and what will the consequences be tomorrow? We ask industry experts from our Transforming Flexo community to share their views and insights both with a short and long view, as we all begin to adapt to a new normal.

Insights from:

Paul Baker, formerly at P&G, Paul Baker is a packaging consultant to major brands and runs Print Management Consultancy (PMC)

Stefano d’Andrea, formerly at Kodak, is an industrial graphic and flexo expert providing training and consultancy. He works with the FTA Europe and Atif, the Italian association for flexography, and is a judge for the Global Flexo Innovation Awards 2020.

Olga Munroe, is head of the Retail Institute at Leeds Beckett University

Sebastian Longo, is president of Fotograbados Longo S.A, and judge for the Global Flexo Innovation Awards 2020.

1. Adjusting to new ways of working

From further embracing remote learning to finding the most effective way to manufacture and stay safe under new guidance, changes to our working day are set to impact flexo businesses for a long time to come.

Paul Baker: “I’ve talked with a few friends in the pre-press industry and they’ve been saying they’re really busy. Of course there’s a lot of working from home, but in our industry we’ve been working with virtual collaboration tools for a number of years, so we’re used to working like that and have adapted extremely well. The biggest challenge in the industry so far has been how to keep employees safe, in a production and manufacturing environment. People flow management systems, segregation, structured shifts and maintaining a functioning flexible workforce are more than just temporary fixes, they will need to be embedded into our working practice longterm.”

Sebastian Longo: “We are having a lot of prepress jobs: new files with new designs; we’re receiving a lot every day. I never imagined people would want to launch new designs during the pandemic, so we prepared a team for fast response to customers, in order to meet that need, all while implementing the necessary health and safety measures for the team working here. Teams would alternate: one team of six people came one day, six from the other team the next. We gave people PPE and set up social distancing measures during shifts. People are working two hours less every day – arriving and leaving the job an hour earlier than normal, to avoid rush hour on public transport. And of course, we’re more flexible with where and how people work.”

2. Responding to demand

The pressure on flexo printers to deliver during this crisis has been unprecedented. This has brought its own challenges in the short term with a long-term impact that also needs to be considered.

Olga Munroe: “In the early weeks of lockdown, restrictions in movement and closures of food outlets resulted in panic buying. Non-perishable groceries, like pasta or rice, toilet paper or cleaning detergents were stockpiled resulting in pressure on all stages of the supply chain. There has been a 49% increase in grocery spend among the UK and US households, as reported by the GWI*. Whether this anxiety about produce availability and its consequent impact on producers continues in the long term, with people hording non-perishables post pandemic, is dependent on the duration of the crisis. We might see other waves of the virus, and in the UK, any hard-Brexit is likely to affect the availability of goods. This could result in future spikes in demand. It might be prudent for businesses to have a contingency for such eventualities, from both the technical and human resource perspective.”

Paul Baker: “Lots of FMCG companies have seen significant growth in the last three months, driven by panic buying. It has recently been reported in the press that P&G has definitely been producing products at record volumes, due to increased demand. Printer reallocations and quick onboarding of peripheral suppliers has been essential for some companies, with the focus on how to get large pack sizes out of the door in maximum quantities.

I think another challenge for printers is the supply of raw materials. Companies have had to look for alternative supply systems to meet their production demands. And qualification of alternative supply systems takes time and resources, and carries a degree of risk. The question will be how sustainable it all is, ongoing, and will there come a point where the demand reduces, from the consumer? Businesses will have to look carefully at how and when they dial things back.”

*Global Web Index, ‘Coronavirus Research: Consumer Spending’, April 2020

3. Quality and standardization

With increased demand at faster speed comes another challenge. Maintaining quality and consistency of print. That’s where flexo comes into its own – and where a new opportunity arises for printers to improve their processes as they adapt and respond.

Paul Baker: “If I think about the businesses that are doing well in this environment, they’re mostly using flexible film as packaging, or corrugated cases, all predominantly printed by flexo. Things like cleaning products often use pressure-sensitive labels, and a lot of those combination presses are predominantly flexo too. Flexo is a mature versatile printing tech, it’s generally a lower investment than others, faster set-up and cost-effective for low-to-medium print runs, and can print in good register on to thin gauges of flexible films at high speeds, I think it’s going to be probably the print tech of choice that many FMCGs will be turning to.”

Stefano d’Andrea: “If I look at flexo printing in these critical months of Covid-19, I see a lot of printers struggling with too much work and sometimes that’s because their processes aren’t improving to maintain quality while meeting demand.

I’ve been having a lot of conversations online with printers since March, who are trying to change the print settings when they’re printing. So that means there’s no real number guiding the process control before going to press. And this is the part that needs to be improved.

Most print buyers are simply aiming for predictability and repeatability. The only effective way to offer this is to know the process before printing. I train people to think across three pillars: understanding every component and variable in the system and how they work; understanding how to interact with colors, related to the measurement, evaluation and color management; and understanding how to calibrate the process in a way that’s able to deliver the expected numbers. Many companies are speaking about using numbers for judgement. I would say, don’t just print by numbers, make sure you know what you’re doing. Sometimes the number itself doesn’t give you the full picture of what’s happening on the printing press.

I think we’re all now trying to survive and revive our business after this situation. How can we do this? One way is to dedicate time to the standardization directions that can deliver efficiency and profitability of the printing system.”

4. Innovation still matters

Despite the difficulties the global pandemic has brought with it, there are too, opportunities. For every problem there is a solution that draws on innovative thinking, collaboration and commitment to change. Something the flexo community has in spades.

Olga Munroe: “There has definitely been a marked shift away from the reduced packaging and plastic pollution efforts as a result of fears around contamination. The coffee chain Starbucks has banned use of personal cups to reduce risks of contamination, temporarily returning to single use cups*. In the US, where at the end of last year nine states have committed to implement bans on single-use plastic. bags, the fears of contamination from reusable grocery bags paused the implementation of the legislation, and consumer are encouraged to use single use bags instead. A recent study from International Food Information Council showed that 43% of survey respondents said that they buy more packaged goods**, however there is no insights into whether that’s due to retailers removing an option of fresh loose produce or consumer perceptions of foods being protected by plastics. Microbial coatings are a popular area many businesses are looking at and innovating in. Safety and material recyclability, rather than complete removal of packaging, might be a trend going forward.”

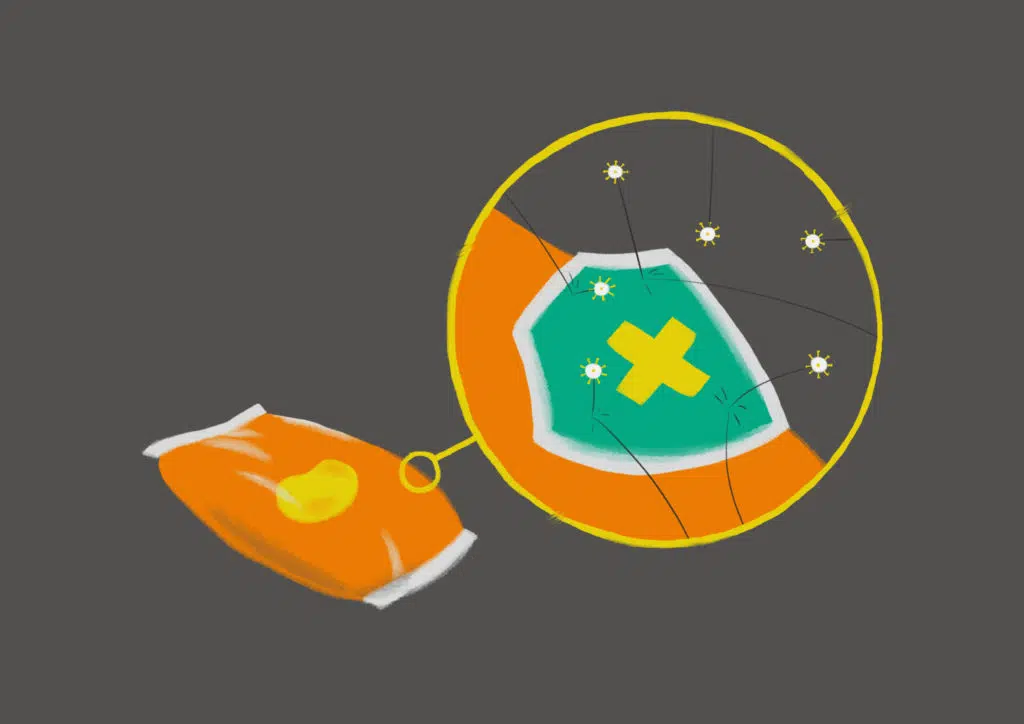

Paul Baker: “Before the pandemic there was a drive towards reuse rather than disposable and I’ve heard along the lines that there may be more packaging designed for single use. This is a big setback for drives towards sustainability. However, it could ramp up the exploration and use of substrates that are both single use and sustainable: bio based, eco-friendly polywraps for example or recycled plastic.

There’s also innovation to develop anti-viral coating, which may well be a very good application to sit with flexo. I saw the British Coating Federation recently got together coating specialists to discuss how different surface tech could be used to tackle the pandemic. I also saw some research in Hong Kong to develop anti-viral coating – which may well be an opportunity for the printing industry in the future: if you could apply anti-viral coating to film or corrugate, it’d all help in the reduction of the transmission of the virus.”