Imageworx succeeds at mission impossible

At first sight, specializing in the impossible doesn’t look like the best way to build a profitable long-term business. For Pennsylvania-based prepress house Imageworx, however, it’s a strategy that has proved highly successful for more than two decades.

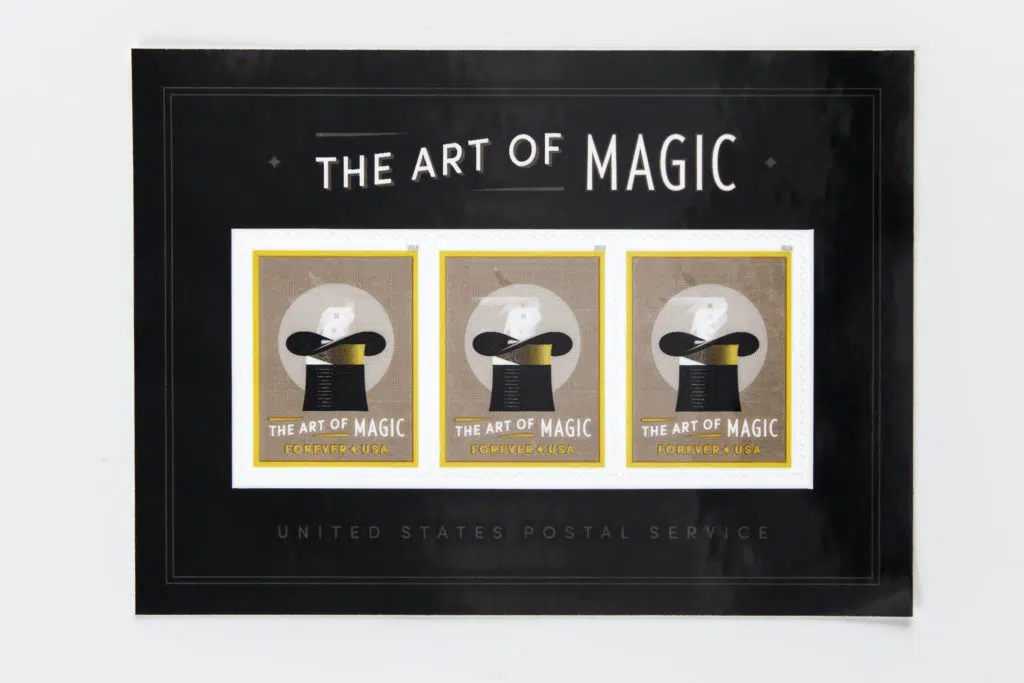

To understand what achieving the impossible looks like, consider the winning entry of Imageworx in Miraclon’s Global Flexo Innovation Awards. ‘The Art of Magic’ postage stamps were notable for two remarkable ‘firsts’: they were the first US postal stamps ever printed flexo, and the first to exploit 3D micro optical printing. Unveiled in Las Vegas by the United States Postal Service — and world-famous magician David Copperfield — three of the stamps featured animated 3D effects, including a white rabbit popping out of a top hat.

Technically Challenging

Micro optical lens printing is technically challenging at the best of times and would be regarded by many as beyond the capabilities of flexo. Jeff Toepfer of Imageworx explains: “Producing art and plates to use with micro lenses is an extremely difficult imaging process, calling for the highest level of precision. To meet the resolution requirements for the stamps, we had to image 139,500 interlaced pixels across the web — and do so with perfect 1:1 pixel integrity to produce the interference patterns that create the illusion of movement.”

He adds that, to the best of his knowledge, Imageworx is the only prepress company in the world currently offering micro-optical lens array prepress for flexography. He also gives due credit to the Kodak Flexcel NX technology: “Nothing else can produce such small images on a flexo plate. Without it, our success in micro imaging would be very limited. It’s incredible.”

He adds that, to the best of his knowledge, Imageworx is the only prepress company in the world currently offering micro-optical lens array prepress for flexography. He also gives due credit to the Kodak Flexcel NX technology: “Nothing else can produce such small images on a flexo plate. Without it, our success in micro imaging would be very limited. It’s incredible.”

Professional Curiosity

If you look beyond the winning entry and into the Imageworx story, it comes as no surprise that Imageworx pulled it off. Here is a company that places technical design innovation at its heart, inspired by what Toepfer describes as “a high level of professional curiosity. We’re constantly working at developing new technologies and improving existing ones.” When Jeff’s father Jerry founded Imageworx in 1997, he did so with a philosophy that demanded the company keep pushing the boundaries of innovation — namely, that if you help customers realize their most difficult projects you will have a customer for life.

At the outset, the business was supplying separations and plates for dry offset and narrow web applications, but today flexo accounts for 90% of the business. The focus, however, remains where it’s always been, on the quality-minded higher reaches of the market, a segment that Toepfer says is growing steadily thanks to the improvements in flexo technology in recent years. “What’s happened has been evolutionary rather than revolutionary, but no less profound for that. Every component — ink, doctor blades, aniloxes, plate mounting, imaging, plates and presses — has steadily improved. As a result, quality is no longer an issue, and flexo is now an economical print process of choice.”

Stunning Quality

And the quality that Imageworx achieves is truly stunning. The company produces plates capable of holding micro text as small as 1/4 -point, and images and holds dots all the way down to 0.2% at 175-line screens. Its proprietary ‘SERO™ HDM’ brand of hybrid screening technology produces perfectly smooth gradations and an extended tonal range, without edges where the dot breaks down. This enables a nearly imperceptible fade to zero, eliminating the need to hold a minimum dot in non-printed areas to avoid the hard break formerly common in flexo. Besides 3D optics, these capabilities have opened up other new markets such as security printing, as well as delivering exceptional quality levels in process color printing.

The “professional curiosity” mentioned earlier means Imageworx doesn’t wait for new markets and applications to come knocking but seeks them out proactively through an R&D department tasked with identifying markets likely to benefit from the company’s advanced flexo technology. The next step is to identify the market’s requirements, develop a suitable product, then test and perfect it.

For print trials, Imageworx partners with flexo press manufacturer MPS, previously using the latter’s demonstration facility in Green Bay, Wisconsin. “The acid test of any new idea takes place on the press,” says Toepfer, “so understanding what happens in the pressroom is essential. The Art of Magic stamps are a good example: in pre-production trials at MPS we successfully ran the job at the 250-feet-per-minute speed the customer demanded.”

A flexo future for flexible packaging

Looking to the future, Jeff Toepfer expects Imageworx’s recent rapid expansion into new markets and applications will continue, as flexo steadily wins work from offset and gravure. “In the wide web market, the major trend we see is migration from more expensive gravure technology.”

On the back of this, he adds, Imageworx is now making significant inroads into the flexible packaging sector. “In just a few years, we’ve seen strong growth in flexibles, to the point where they now account for around 35% of our work, mostly shrink-wrap and bag materials for consumer products.”

He attributes the success to the combination of Kodak Flexcel NX and SERO™ HDM. “Wide web printers have often struggled to reproduce highlight dots. SERO and Flexcel NX enable high-resolution imaging and finely tuned, microscopic dot structures, broadening the color gamut for flexo printers by delivering a smoother breakdown of highlight dots. We have the ability to determine ideal dot structures on the plates, delivering top-quality results on short-run jobs. We can also apply separate screening algorithms that maintain dot stability on long runs, even beyond 1 million impressions.”

Toepfer adds that productivity increases. “Press speed is a major purchasing factor in flexible packaging pre-press and plates. Sero HDM and Flexcel NX have allowed some customers to increase running-speeds by up to 500 feet a minute.”

Concrete evidence of confidence

The company’s recent move into a new 31,500 square foot facility is concrete evidence of that confidence, which is based on what he regards as the overwhelming economic logic in favor of flexo. This includes the new Flexo Excellence Center, which includes an MPS press enabling all future testing to be on-site for faster feedback in their testing and more rapid development. “If people ask me if we have a strategy for persuading clients to move work to flexo, I reply that we don’t need to. We promote flexo, of course, distributing print samples showing the quality flexo achieves on difficult images, but in the final analysis the economic reality is inescapable — flexo is a more economical technology for the end user, and one that no longer calls for a compromise on quality.”

“Market acceptance can be slower than we’d like, but sooner or later, if the buyer is print-savvy and experienced, all print jobs wind up with the process that most benefits the job. If someone wants 2,000 labels, it’s probably a digital job; if it’s 2 million, that’s flexo; 200 million, maybe gravure. Print quality is not the issue, so economics drives the buying decisions. We will overcome this through the value flexo offers.”

He also expects the equipment investment cycle at printers and converters to work in flexo’s favor. “Older equipment is being replaced with new technology capable of better register, more consistent print, and easier set-up. All in all, it’s only a matter of time before the decision to replace offset and gravure for more relevant products will become obvious and unavoidable.”