DELTASACS meets flexible packaging market expectations with KODAK FLEXCEL NX System

Friday, July 20, 2018 —

Almost a century-old, Deltasacs is the European leader in small and medium-sized bags. Cardboard-bottomed bags, flat bags, stand-up pouches with zip or cap closures, printing of film to be delivered on reels, de-metallization and lamination are all products on which the reputation of the manufacturer is well anchored.

Its clientele is made up of big names in the food, drugstore and cosmetics industries as well as packaging distributors for cardboard bags. With two production sites in France (Pont Evêque in Isère and Saint-Jean de Muzols in Ardèche) and a site in Budapest, Hungary, Deltasacs employs 45 people and has a turnover of 7 million euros, of which 25% is international. A committed company, Deltasacs scrupulously respects the environment throughout its production flow. In addition, Deltasacs is ISO 9001 certified for the quality of these processes and ISO 22000 for food safety.

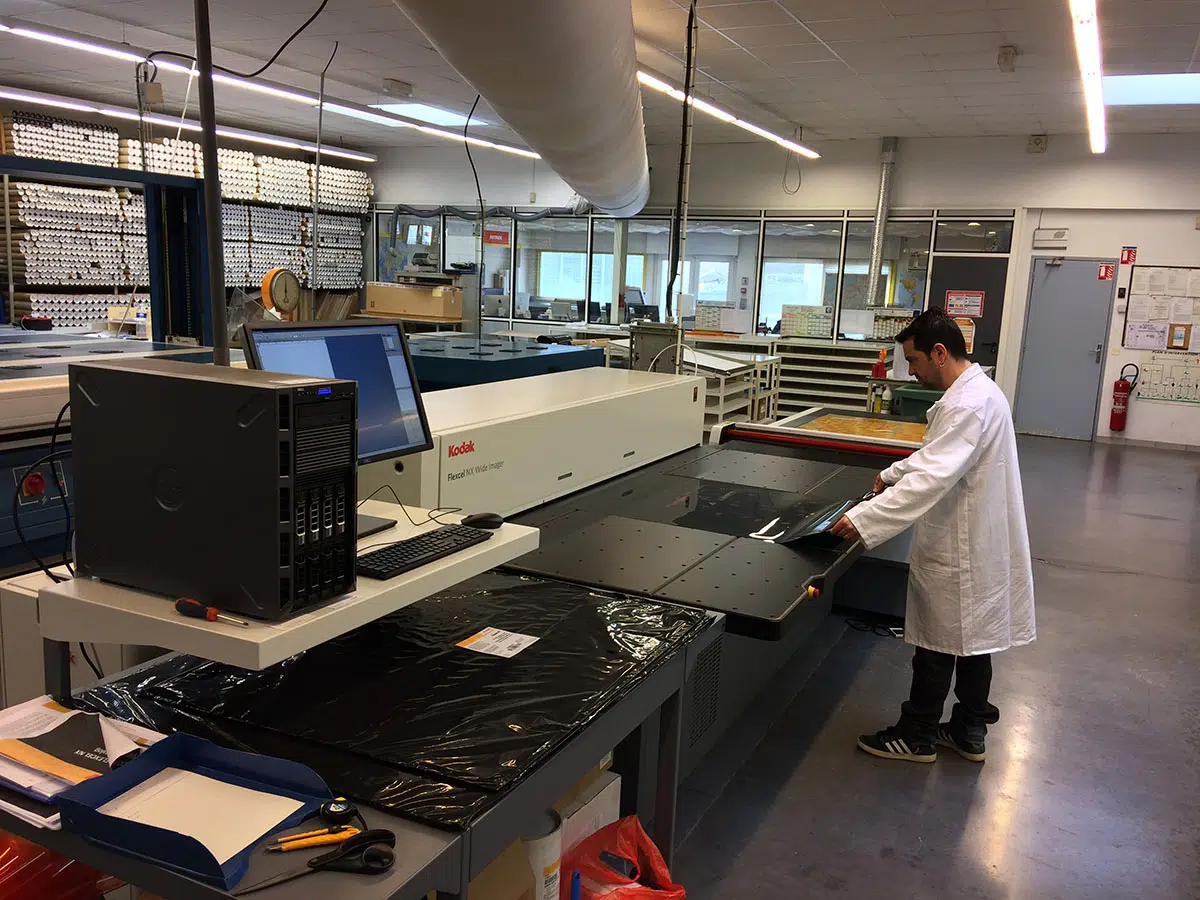

After a careful study of what the market offers, Deltasacs chose the KODAK FLEXCEL NX Wide 3548 System. “We found in Kodak, with its imaging system and its FLEXCEL NX plates, an opportunity to meet the expectations of the market for image reproduction and consistent plate production,” says Site Director Laurent Perrier.

Two months after installation, the KODAK FLEXCEL NX System is already opening new markets for Deltasacs: “The print quality of the FLEXCEL NX is exceptional. From a technical point of view, we can now accept work that requires very fine gradient,” says Perrier.

When Deltasacs performs tests for its customers, the positive returns are not long in coming. Alongside the infinite possibilities and a clear and bright image, Perrier emphasizes the widening of the color gamut and the predictability of the colors. “Run after run, from one reprint to another, the colors always match. This saves us a lot of time,” he adds.

In the press room, the FLEXCEL NX System – appreciated for its ergonomics, compactness and ease of use in prepress – offers great flexibility in printing. “The precise nature of the plates is greatly reducing set-up time. As a result, we are very competitive with digital printing and can now position ourselves for quantities as low as 5,000 pieces,” says Perrier. An important asset for Deltasacs because it allows customers to more closely fine tune their products to their market and to adapt in real time to regulatory changes.

Deltasacs continually strives to innovate with their product offerings. For a brand of organic fertilizer, the company recently made a stand-up pouch simulating a textured and granular material. “The brands that make organic are very attentive to the environment. The stand-up pouch interests them by its eco-design. Not only is the weight of the packaging minimized compared to the quantity packaged, but to the touch, the sensation is not that of a plastic bag,” says Perrier. “The KODAK FLEXCEL NX System can handle all technical challenges and enhance the impact of products on the shelf.”

Perrier concludes: “We wanted to find the technology to obtain the best possible results and make the most of our flexo presses. The KODAK FLEXCEL NX system meets our expectations.”

Gilles Corbé, Sales Manager, Kodak France, adds: “One of the main benefits of the FLEXCEL NX System is to simplify the prepress and flexo printing processes. We are very happy to contribute, at our level, to the success of Deltasacs.”