How to Troubleshoot Print Issues

Knowing exactly where to look when problems arise on press – from inspecting DIGICAP NX patterning to monitoring ink drying speeds – means finding solutions quickly and maximizing press time. Catherine Green, Global Product Support Manager shows the way.

Whether you are new to KODAK FLEXCEL NX Plates or are a seasoned veteran, unexpected print results can arise – resulting in unwanted downtime if not resolved quickly.

Knowing exactly where to begin troubleshooting common print issues means you can avoid unforeseen press stops and find solutions to keep presses running. Here, we look at steps to take in the plateroom and the pressroom:

- Selecting and inspecting KODAK DIGICAP NX patterning

- Matching and maintaining anilox rolls

- Ensuring quality finishes through correct ink drying time, impression setting and plate inspection

- How ink viscosity and plate finish impact effective ink transfer

- Where to find out more about print specification setting – the key to profitable printing

- Core aspects of plate care

DIGICAP NX Patterning: Performance on Press

Selecting the Correct DIGICAP NX Pattering:

The process beings with a print test to determine the correct DIGICAP NX patterning for the application. This single-color test plate contains a variety of patterns which are evaluated for density, opacity, and optimizing ink laydown for various screens, including small reverse and positive type. This test plate can be printed in a variety of conditions (or s part of a banded anilox test) to determine the ideal pattern for process colors, spot colors, white inks and coatings. This DIGICAP NX test target is available for download from Partner Place (Answer ID: 71194) so you can carry out the test as your print conditions change, but Miraclon’s Technical Applications support team is also available to assist with this process as needed.

Anilox Selection & Condition:

Once the correct DIGICAP NX patterning is in place, it must receive the correct volume of ink to print properly. The most common issues that cause low solid densities or pinholing when using DIGICAP NX patterning are related to improper anilox selection or dirty/pluggeed anilox rolls. Confirm that the correct anilox is being used for the DIGICAP NX patterning on the problem separation (process, spot, white or coating), and if it is correct, inspect the roll to ensure it is clean and not excessively worn. If you are unsure of the condition of your anilox rolls, contact your anilox supplier to audit your inventory and provide insight into the overall condition of your anilox rolls.

Inspecting DIGICAP NX patterns on the Plate:

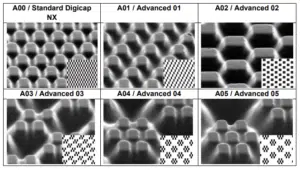

Along with confirming proper ink delivery to the plate, it’s important to also confirm the correct DIGICAP NX patterning was applied to the plate and confirm the plate is in good condition. With a little practice, it’s easy to inspect the plate and identify each pattern with a 100x optical microscope. USC or digital microscopes can work, but sometimes the resolution of the digital image can make it difficult to see the pattern. The images below show each pattern as a TIF file, and its appearance on the plate surface.

Click here to see a how-to video: Inspecting DIGICAP NX

Highlight Print Quality

Solvent Ink Drying Speed:

Ink dry rate is possibly one of the most overlooked variables when troubleshooting highlights. If the ink is drying too quickly, it can dry on the tiny surface area of the highlight dot faster than the rest of the plate, causing the appearance of highlight dot loss and hard edges. Continuing to run in these conditions will cause dried ink to build up on the shoulder of the highlight dots, leading to dirty print, in addition to the previous issues. Work with your team to ensure proper drying velocity on your equipment, and that air is not being blown back or diverted back to the plate. In addition, work with your ink vendor to find the right solvents to balance drying speed and print performance with solvent inks.

Impression Setting:

Setting plate to substrate impression is a basic function of start-up. How do you know you’ve set impression properly? Adding impression targets to both sides of the web can be extremely useful for setup and troubleshooting. These hexagon-shaped targets are designed with a series of thin lines that indicate over-impression in two ways: an “hourglass” shape appears in the press direction when over-impression exists between the plate and substrate; or a “bowtie” shape appears when over-impression exists between the plate and anilox roll. FTA’s FIRST 6.0 outlines detailed use of these targets and is a great resource for any flexographic printer.

Plate Exposure & Relief:

Process control in the plateroom is an important part of success in the pressroom. Miraclon recommends that every plate be inspected for proper relief and exposure. Proper relief ensures the plate has the correct back exposure, providing a stable foundation for highlight dots to not only form on the plate, but to print properly and hold up under the pressures of the printing process.

A simple UVA main exposure target can provide valuable insight into the formation of fine features on the plate, ensuring the plate receives the proper UVA exposure and processing conditions. These targets are available for download on our Partner Place portal. For more information, see Partner Place Answer ID 62379.

Ink Transfer

Proper ink viscosity:

Viscosity is another fundamental factor to check when troubleshooting print issues with both solvent and water-based inks. If the ink is too viscous it will impede flow, therefore hindering proper ink transfer throughout the system. This can lead to print defects such as density shifts and ink trapping issues. Your ink vendor will have a recommended viscosity target for your specific ink set, so be sure to obtain that information and measure often.

Plate Surface Properties:

Light finishing, the final step in the platemaking process, can impact ink transfer. If the plate receives too little or too much UVC light exposure, unexpected results on press can occur.

Too light UVC exposure will result in a plate that is tacky to the touch and does not properly release ink to the substrate. Too much UVC exposure will result in a place that cannot effectively collect ink from the anilox roll. This produces low densities on press and even physical damage to the plate surface in the form of surface cracking. To optimize your FLEXCEL NX plate finishing, refer to the Partner Place Answer ID 66700.

Printing Consistently

Running to a Specification in the Pressroom:

Printing predictably means printing more profitably.

Printing to a specification is the foundation flexographic process control. All aspects of the flexographic process from design, to prepress, to printing, rely on a predictable, repeatable printing environment. These specifications can include (but are not limited to) measurements of spectral data, density, dot gain, and white opacity. For guidance on setting initial print specifications, see Partner Place Answer ID 62383.

Also, FTA’s FIRST guide is a valuable resource for anyone involved in the flexographic industry. Many of Miraclon’s technical experts have earned their FTA Level III – Implementation Specialist certifications. We are available and ready to provide guidance for our customers as they implement FLEXCEL NX technologies.

Plate Care

Impression and Plate Life:

Over-impression is one of the leading causes of plate damage. The excess forces exerted on the plate cause faster plate wear, increase print defects, and can exaggerate issues such as plate swelling. Setting ‘kiss impression’, or the minimum amount of required impression to achieve complete print, is the best starting point for each setup. Once kiss impression is achieved, control targets should be measured to verify compliance with the print specification. Running with kiss impression whenever possible will ensure maximum plate life.

Cleaning & Chemicals:

Most printers have experienced an issue with an aggressive chemical interacting with the plate as some point. Miraclon provides a list of common pressroom chemicals and their compatibility with FLEXCEL NX Plates. It is a good idea to familiarize yourself with these chemicals and ensure that pressroom and cleaning activities are not utilizing chemicals that are known to damage FLEXCEL NX Plates.

On press, the most common symptom of a chemical interaction issues is excessive dot gain – a result of plate swelling and softening as it reacts with an incompatible chemical. Sometimes working with an aggressive ink or coating unavoidable, but with some preparation ahead of time, you can minimize the chance for unexpected issues. For a list of chemicals and more information on cleaning plates, see Partner Place Answer ID 62385.

Maximizing press time

With a little preparation and planning, you can optimize your print process, maximizing valuable press time. We’re on hand to help you get the best from your FLEXCEL NX Plates. We also recommend exploring the training and development opportunities that industry associations provide as well as the resources your suppliers make available.

Knowing where to look to troubleshoot and avoid unexpected print problems means creating repeatable and predictable printing, with less downtime.

Knowing where to look to troubleshoot and avoid unexpected print problems means creating repeatable and predictable printing, with less downtime.

This begins at selecting and testing the plate pattern and goes through to ensuring the ink isn’t drying too quickly, impairing the finish. Find out where to look and the steps to take.