How to handle and store your plates for improved plate life and performance

Flexo Printing Application Specialist, Fabio Rocha, explains how using, handling, and storage best practices are essential for plates that can be re-used time and time again, delivering efficiencies and savings.

Using handling and storage best practice is essential for plates that can be re-used time and time again,

delivering efficiencies and savings.

Why taking care of your plates make a difference

- Mounting: Good contact between plate and sticky back tape helps avoid plate life during the printing, resulting in fewer press stops;

- Demounting: Using care to gently remove plates from cylinders will help avoid tearing plates; always peel slow and low

- Cleaning before and after the print run: Following these best practices will results in an excellent performing plate on press, with high repeatability and reproducibility.

- Storage: Storing photopolymer plates in recommended conditions can lead to prolonged plate life, repeatability on press, delivering cost savings.

Plate Mounting

- Ensure that the back of the plate is clean and free of debris by cleaning the back of your plates before mounting with Isopropyl Alcohol (IPA). IPA is the best solvent for cleaning the back of your plates. This is especially important with new plates because it removes the residue left on the plate from solvent processing.

- Make sure your cylinder is clean and dry before mouning your plate; this will also help reduce plate life and plate damage.

- Apply sticky back tape to your cylinder by following the manufacturer’s guidelines. Now you are ready to mount your plate.

- Use a rubber roller to carefully adhere your entire plate around the cylinder, while removing all air pockets. This will help ensure uniform contact.

Plate Demounting

- Demount your plate immediately after a run to avoid ink drying on the plate surface.

- After the run, peel the plate slowly away from the cylinder to avoid tearing the plate.

Manual Plate Cleaning

- Be sure your plate cleaning solution is compatible with your ink type and plate type (check the manufacturer guidelines)

- Gently clean the plate with a soft horsehair bristle brush to remove ink from the plate surface; aggressive cleaning and scrubbing can damage your plate surface and patterning.

- Clean the back of the plate with IPA to remove any residue of inks and/or varnishes from the print run.

To see more detailed instructions on how to properly clean your plate and what cleaning agents are compatible, please check out our Plate Cleaning Guide.

Automatic Plate Wash Systems

- Be sure your plate cleaning solution is compatible with your ink type, and plate type. (check the manufacturer’s guidelines)

- Verify optimal temperature of the cleaning solution and drying systems in the automatic plate washer.

- Clean the back of the plate using IPA after the plate is removed from the automatic plate cleaning machine to remove any remaining residue from inks or cleaning solutions.

Plate Storage After Cleaning

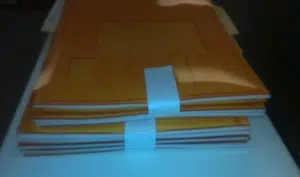

- Always store plates facing down and flat when possible.

- Interleave the white foam from your plate boxes in between clean/dry plates to protect all print surfaces (Figure 1).

- Protect your plates from UVA light by packing the set of plates (job) with foam inside sealed brown kraft paper or a sealed back poly bag.

- If storing on cylinders or sleeves, always wrap the plate with black poly wrap and ensure ends are sealed.

- Always protect your plates from ozone gas by storing them away from heating vents, cooling vents, or equipment where ozone may be present (for example, a corona treater or electrical transformer). (Figure 2)

- To protect your plates from high temperatures, they should be stored in a controlled environment.

Figure 1: How to pack plates and How not to pack plates

Figure 2: Example of plate surface cracking from ozone

Fabio says:

How you care for your plate before and after a press run is an essential part of the printing process. When plates are properly cared for, you can benefit from prolonged plate life and guarantee excellent results on press.

How you care for your plate before and after a press run is an essential part of the printing process. When plates are properly cared for, you can benefit from prolonged plate life and guarantee excellent results on press.